Zinc Caps

Corrosion is the result of electrochemical activity – galvanic action. Scientific studies have proven that metals having a higher electrical potential will corrode and degrade in a typical corrosion cell, while protecting other metals having a slower electrical potential. Of all metals, Zinc has the highest electrical potential.

The most common type of corrosion cell is a simple Battery. The outer case is made of a zinc alloy having a negative charge – the anode. The center post is a carbon rod having a positive charge – the cathode. Separating the two is a filler – the electrolyte. In operation, the positive current charge rushes from the zinc anode to the cathode, causing eventual pitting of the zinc case. As the electrochemical activity stabilizes, the battery loses strength. The aggressive nature of the electrolyte determines the current output and the life of the battery.

The same phenomenon occurs in submerged water and gas mains. The pipes and fittings are buried in an electrolyte – the moist soil. The unprotected lines and fittings, the cathode, have a positive charge and the current generated is discharged directly into the soil in the electrochemical process of corrosion. Corrosion failures of water and gas mains are directly related to the failure of either the bolt/nut combination, or the flanges secured by the combination.

By adding a sacrificial metal – zinc caps – the natural current flow is altered, flowing from the anode (the zinc caps) to the cathode (the pipe and fittings), through the electrolyte (the moist soil) – preventing corrosion.

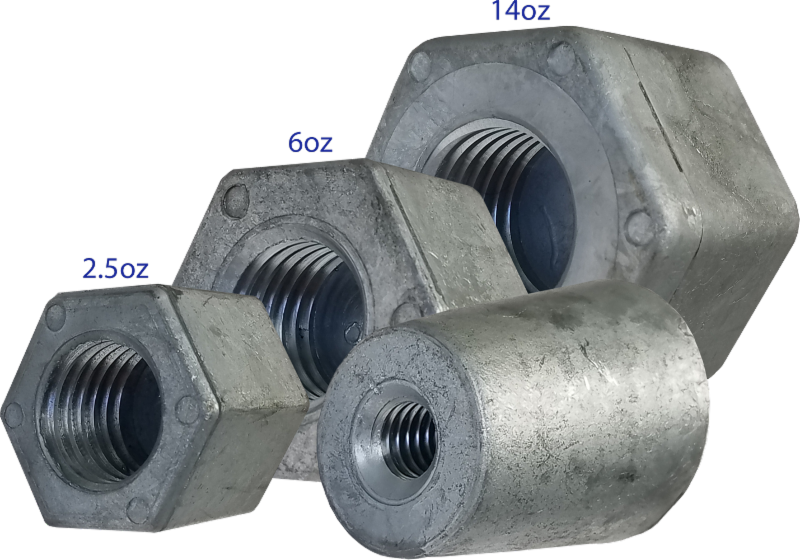

Specifications

Zinc anode caps should be used on buried or submerged pipeline fittings, valves, flanges, bolts, couplings, and hydrants.

- 2.5 oz. Hex: Thread size 1/2″, 3/8″, 5/8″, and 3/4″

- 2.5 oz. Tapered: Thread Size 5/16″, 3/8″, 1/2″, and 7/16″

- 6 oz. Hex: Thread size 1/2″, 5/8″, 3/4″, 7/8″, 1″, and 1-1/8″

- 14 oz. Hex: Thread size 1-1/8″, 1-1/4″, 1-1/2″, and 1-3/4″

Brochures and Datasheets

Diversified Products Brochure 3.20 MB 1362 downloads

MARS Company Diversified Products come in many sizes, lengths and configurations...Zinc Caps Datasheet 173 KB 296 downloads

Corrosion is expensive, protect your investment! A common sense approach to corrosion...

Is your Water Meter Test System ANSI/AWWA C715-18 Compliant?

MARS Company offers the first and only Test Bench Equipment Upgrade Program, enabling customers to upgrade their existing MARS test bench equipment to comply with the ANSI / AWWA C715-18 industry standard.

Is your Meter Shop Certified?

With MARS Maintenance Calibration Certification (MCC), you can protect both MARS and select third-party equipment with calibration, technical assistance, software upgrades, preventative maintenance, training, spares management, and on-site maintenance.